Chemical etching is a very important process used for shaping metal components in various industries. It happens when strong acids or alkaline solutions dissolve parts of the metal surface.

The purpose of chemical etching

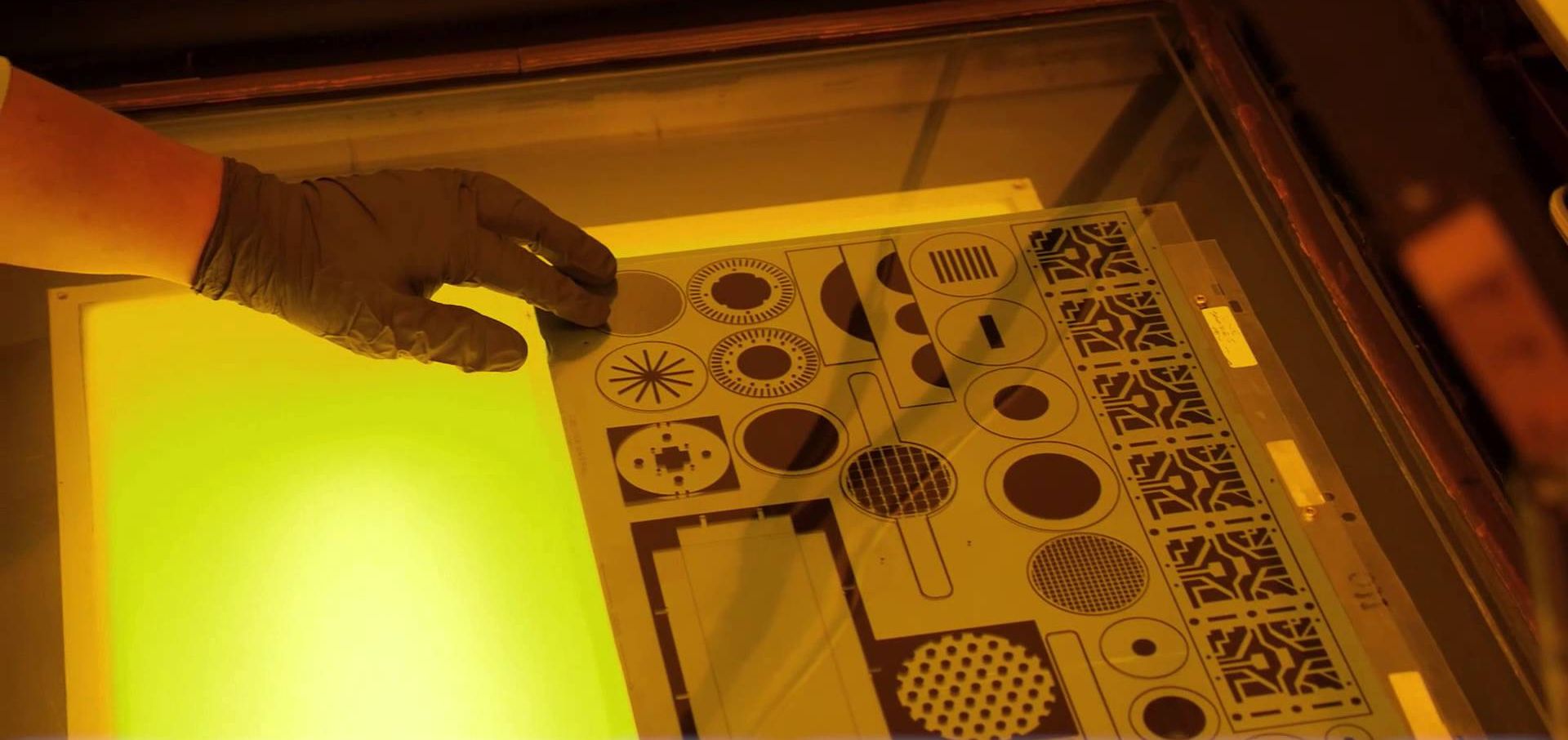

There are virtually no limitations placed upon part geometries by the etching process. All two-dimensional shapes can be etched to enhance functional performance when optimized by designers. Weight-loss holes, contours, ribs, and grooves boost weight-strength ratios: cooling channel intricacies that accomplish the levels, surface areas configured for particular purposes.

A high degree of repeatability characterizes the controls in the chemical etching process. It means successive parts show slight measurable variation and stay virtually identical. For applications such as optical filters or medical devices requiring precise mating across batches at regular intervals, chemical etching offers the needed reproducibility. Consistency is such that an etch recipe can be used for many years.

Chemical etching is a cold fabrication method without melting, so it does not affect the original metal’s mechanical attributes or temper. Parts always retain their as-delivered hardness and other desired characteristics like spring properties and axial fatigue strength that could change from other processes. Metal orientation remains unaltered during this process, leaving metal directional qualities undisturbed by etching.

The etching process has no burrs, slag, sharp edges, recast layers, or heat-affected zones. The dissolved surface has a smooth matte finish that does not require extra debarring operations. For applications interfacing with electronics or seals, edgeless features are safe.

Compared to machined, stamped, or forged parts, chemically etched surfaces result in better bond strength when applying other coatings like plating, painting powder coating, or adhesive bonding. Through contact pressure, mechanical processes iron out these microscopic valleys and anchor points on the etched surfaces.

Modern chemical etching equipment comes with numerous safety interlocks and alarms. Avoidance of operator exposure during part transfer through either sealed containers or automation. Ventilation maintains a safe work environment while fumes are confined using air extraction systems. Personal protective equipment is required for proper handling, whereas facility managers follow industry standards to ensure worker safety and health.

The technology is not new; it has been around for over 80 years and is all-purpose, from tiny micro-circuits to large decorative panels. At reputable etching shops, skilled technicians review customer designs, determine the most efficient etching path, and educate designers based on practical years of experience.

Finally

However, chemical etching surpasses conventional fabrication methods in various aspects when intricate metal parts require close-tolerance precision and design flexibility. Compared to others, which are expensive, etching is affordable and easily accessible, making it support lean manufacturing practices as well as accelerating product development cycles.